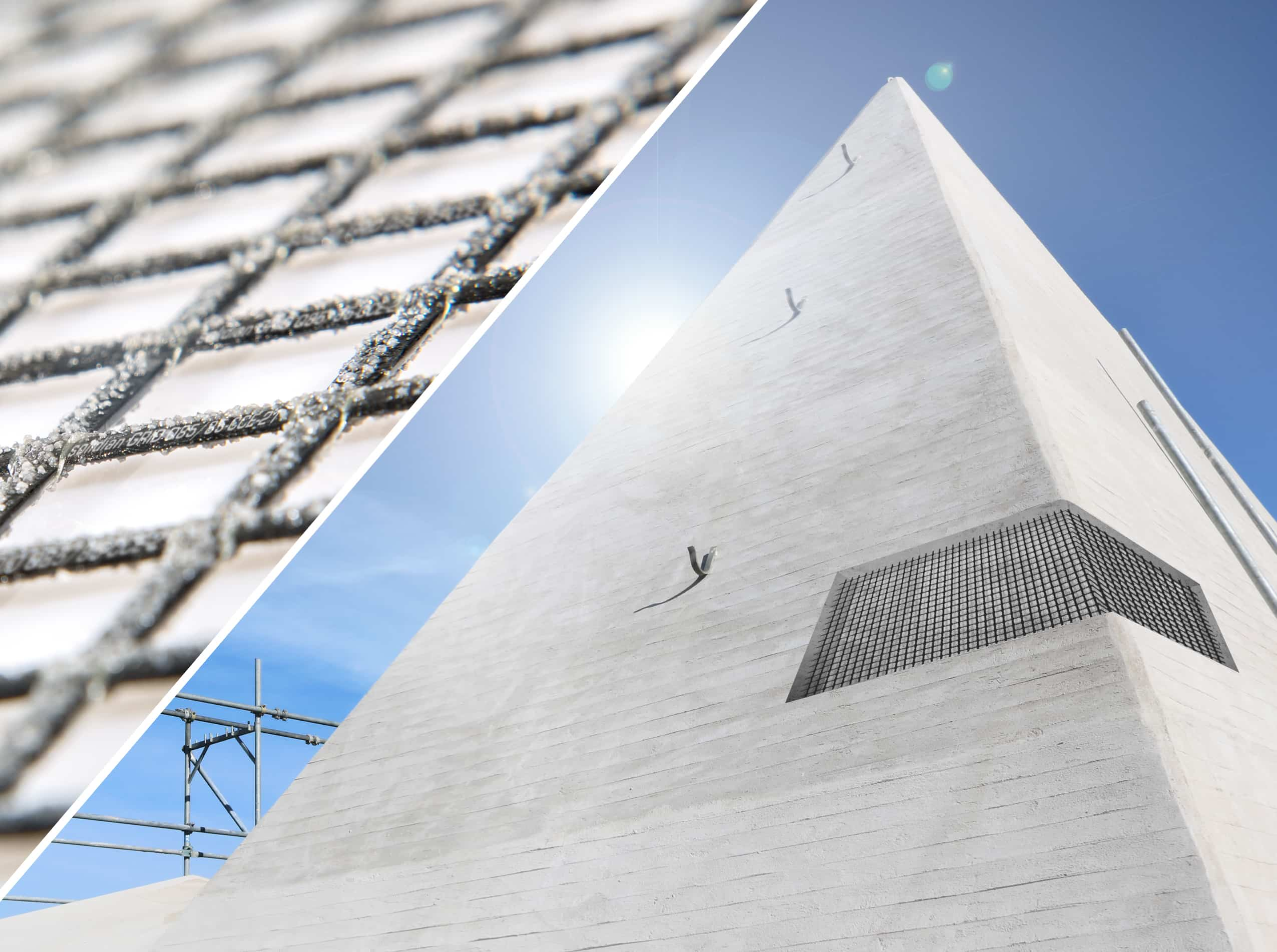

ANTICRACK

solidian ANTICRACK nudi mnoge prednosti u usporedbi s konvencionalnom konstrukcijom od armiranog betona. Najveća prednost naše armature za ograničavanje pukotina za beton je nekorozivni materijal s vrhunskim prianjanjem – to rezultira mnogim prednostima za budućnost gradnje betonom.

Značajke proizvoda

- Brušena površina za vrhunsko lijepljenje

- Veća vlačna čvrstoća u usporedbi s konstrukcijskim čelikom

- Mnogo lakši i tanji od čelika

- Održivi materijal jer je potrošnja vode, pijeska i cementa značajno manja

- Tanje i sigurnije komponente i time manja potrošnja sirovina i ekonomičniji transport

- Bez korozije

- Manje širine pukotina i stoga puno niži troškovi popravka

ojačanja za buduće generacije

Reference project

Primjene proizvoda

Ravna i lagana armatura kao što je solidian ANTICRACK može se koristiti gdje god postoje zahtjevi za ne-korozivnim okruženjem, posebno sa zahtjevima za ograničenje širine pukotina, optimalnu distribuciju pukotina i kratke duljine sidrišta, npr.

- Restauracija, parkirališta, industrijski podovi

- Hidrotehničke građevine

- Popločavanje i hidroizolacija: bazena, podruma

- Zaštitni slojevi, gdje se betonski slojevi nanose na čelično-betonsku podlogu za zaštitu podzemlja

- Mjere ojačanja za restauraciju (npr. otkazivanje donje ploče zbog prekomjernog opterećenja)

- Pomorska gradnja, potres, konstrukcija mostova, konstrukcije koje zahtijevaju male širine pukotina

- Product & Technical Compatibility

- Process Efficiency & Performance

- Use Cases & Application Support

- Which composite manufacturing processes are your reinforcements compatible with?

- Are they compatible with automated production environments?

- How do your reinforcements help improve production efficiency?

- Can your reinforcements be adapted to our production setup?

- Can you help us choose the right reinforcement for our project?

- Are your products suitable for visually demanding applications?

- In which industries are your glass fiber reinforcements commonly used?

često postavljena pitanja

Our products are suitable for pultrusion, RTM, vacuum infusion, filament winding, and other continuous or closed-mold processes.

Yes. kelteks FreeMat and other glass reinforcements are optimized for high-speed production, offering clean handling and consistent quality across long production runs.

Our products ensure fast resin flow, excellent fiber wetting, and consistent fiber placement, leading to shorter cycle times and reduced scrap rates.

Yes. We can customize roll widths, formats, surface weights, and roll lengths to meet the specific needs of your process or equipment.

Our team provides technical guidance and product samples to help you test and select the best solution for your application.

Yes. Thin reinforcement layers like kelteks FreeMat become nearly invisible after resin infusion, making them ideal for transparent or aesthetic surfaces such as toboggans, water slides, and decorative panels. Check the product gallery here.

Our reinforcements are used in industrial equipment, construction components, transportation, electrical infrastructure, and marine applications. A key segment is the recreational industry, especially waterparks, where materials must be durable, non-corrosive, and visually appealing.