Earthquakes pose a significant risk to reinforced concrete (RC) buildings, often causing severe damage to infill walls, which are crucial for structural stability. Traditional unreinforced infill walls tend to crack or collapse under seismic forces, leading to injuries, losses, costly repairs and compromised building integrity.

One proven solution is bed joint reinforcement, which enhances the seismic performance of infill walls by improving strength, energy dissipation, and displacement capacity. By reducing damage and increasing earthquake resistance, this method offers a cost-effective and reliable way to improve the safety of RC structures.

In this article, we share insights on:

- How bed joint reinforcement enhances earthquake resistance

- The key advantages compared to non reinforced infill walls

- Challenges in implementation and how to overcome them

- Real-world examples of its effectiveness in seismic regions

Read on to learn why bed joint reinforcement is becoming an essential strategy for earthquake-resistant construction.

Why are infill walls in RC buildings vulnerable during earthquakes?

Infill walls in RC buildings are typically made of masonry materials like bricks or AAC blocks. While these walls provide partitioning and thermal insulation, they are not designed to withstand lateral seismic forces.

During an earthquake, these walls tend crack and collapse because they are not designed to keep up with the seismic behaviors of the load bearing structure. Once damaged, they no longer are as resilient as before for a further seismic event, since these walls lost their integrity due to shear cracks.

How does bed joint reinforcement improve the seismic performance of infill walls?

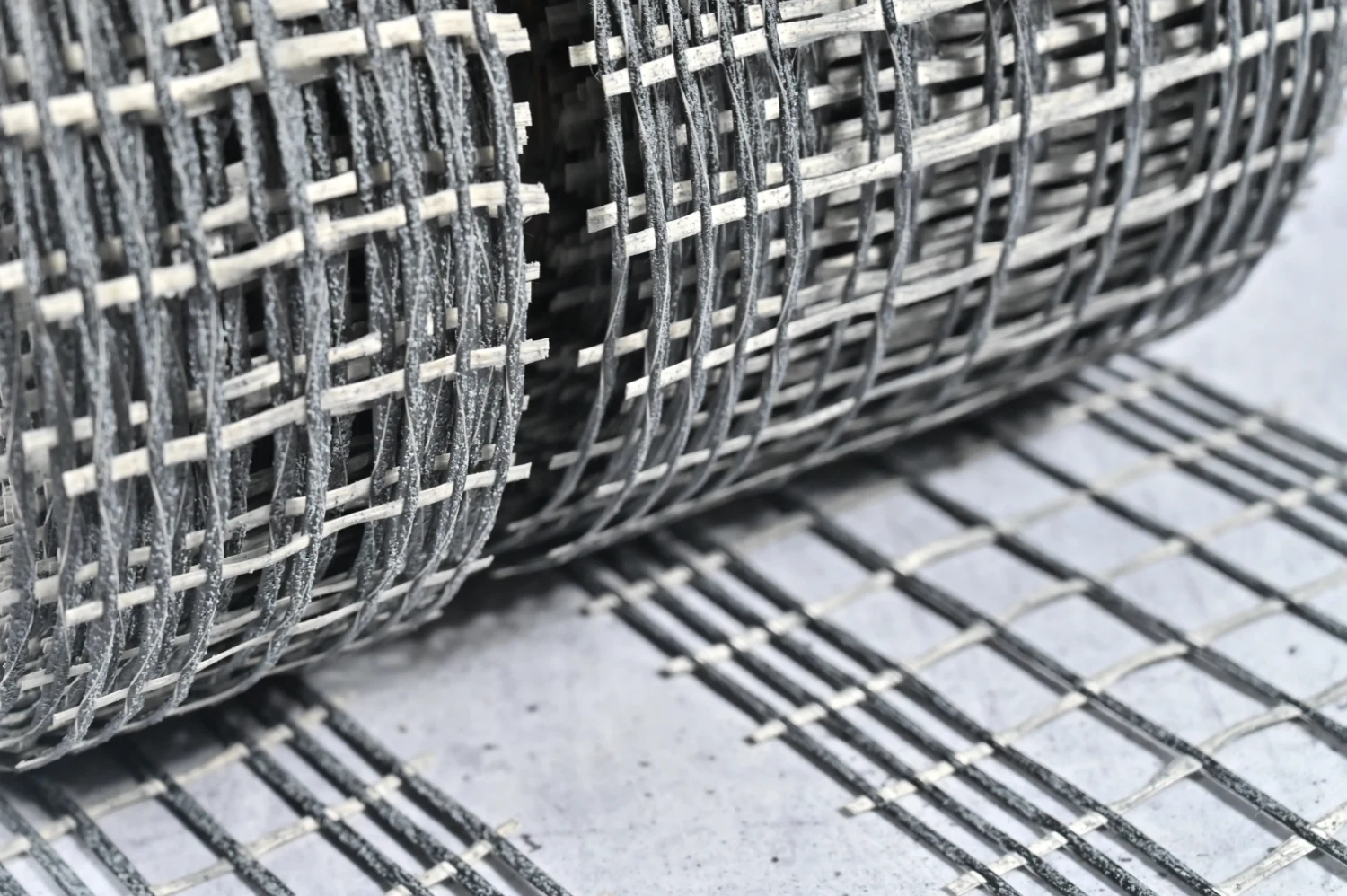

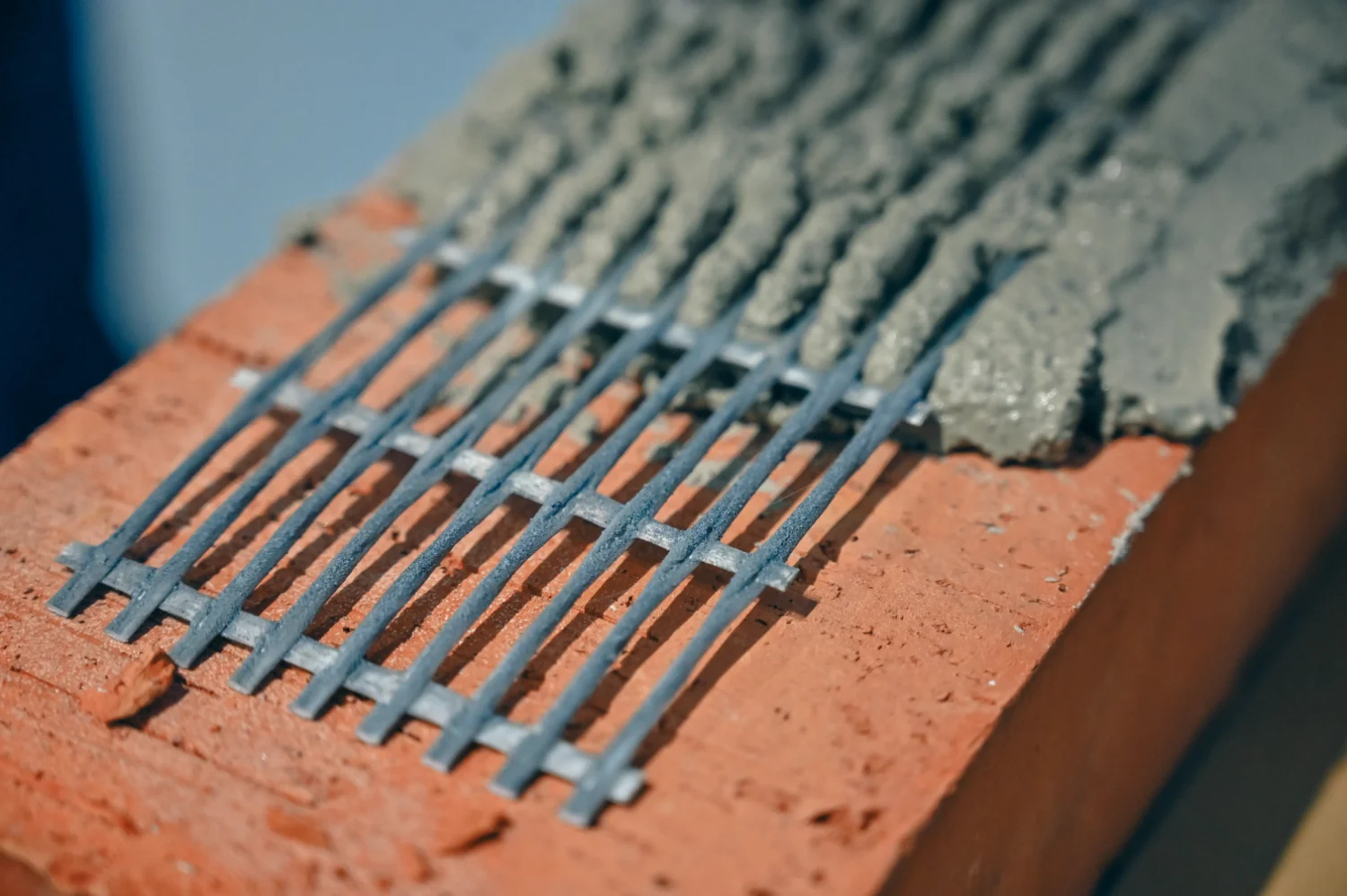

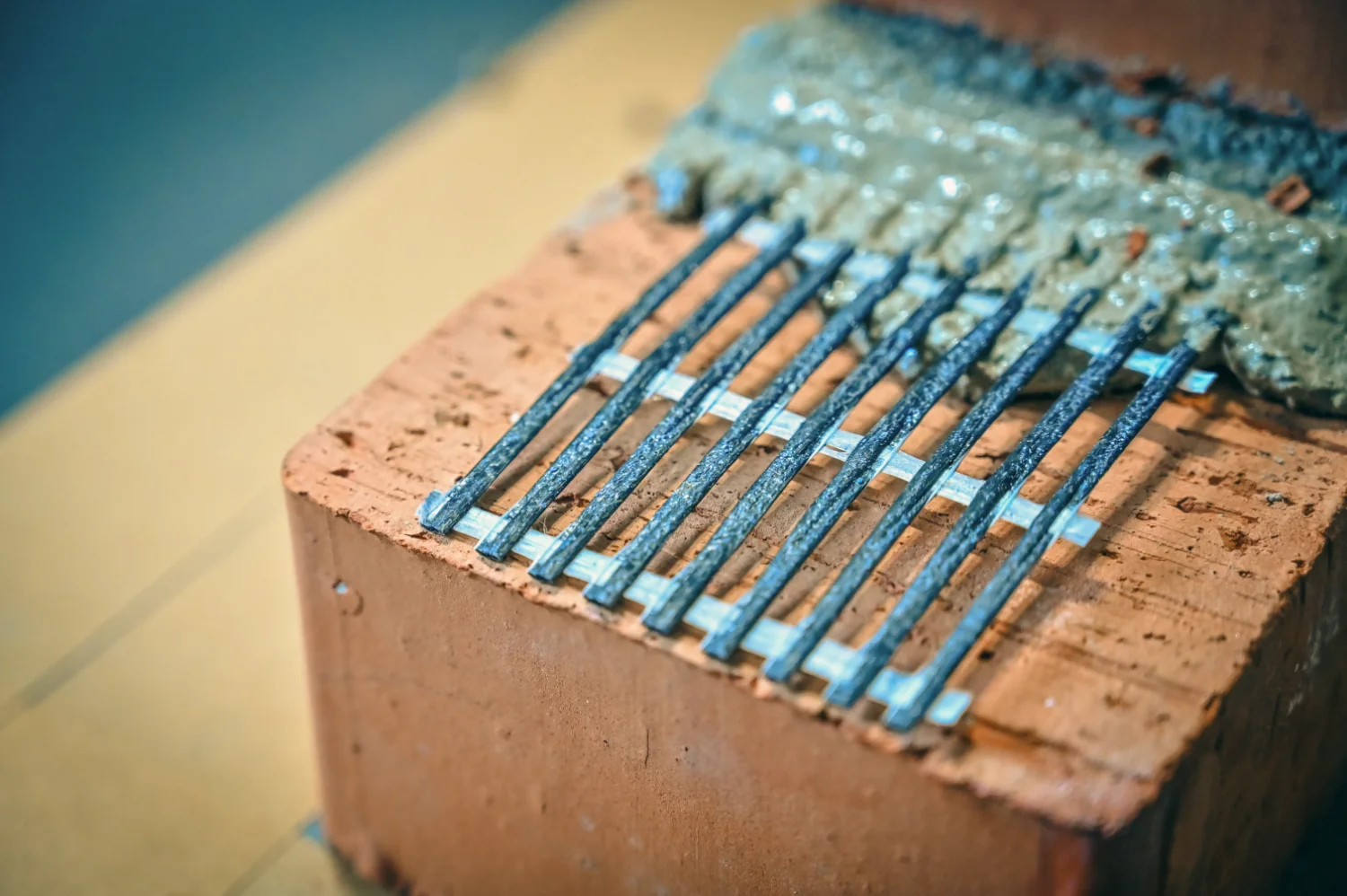

Bed joint reinforcement involves placing steel or non-metallic reinforcements (such as glass or carbon grids) within the mortar joints of masonry infill walls. This reinforcement significantly improves load distribution, controls crack formation, and increases wall integrity during seismic events.

Thanks to this improved load distribution and crack control, the wall can better handle both horizontal and vertical seismic forces. It also absorbs more energy during a quake, which reduces the overall stress on the structure. The reinforcement gives the wall more flexibility, so it can move without breaking apart — lowering the risk of sudden collapse. And since the damage stays minimal, most walls remain usable after moderate earthquakes, which saves time and money on repairs.

What are the key advantages of bed joint reinforcement compared to traditional unreinforced infill walls?

Traditional infill walls, especially those without any reinforcement, are quite brittle and tend to fail under seismic stress. Bed joint reinforcement directly addresses this weakness. By stabilizing the wall, it not only improves its strength but also its ability to stay intact during an earthquake. With reinforced joints, the wall gains more resistance to cracking and shear forces, reducing the chances of total failure.

Research supports this—tests have shown that bed joint reinforcement can increase a wall's horizontal load-bearing capacity by up to 25%. That means a much lower risk of collapse. On top of that, the reinforcement improves how the wall absorbs and distributes energy during a quake, cutting stress on the rest of the building by as much as 30%. All of this leads to stronger structures, fewer repairs, and more confidence in the building’s long-term safety.

Is bed joint reinforcement a cost-effective solution for earthquake-prone areas?

Absolutely. While there is a small initial investment, the long-term savings outweigh the cost. Preventing damage means lower repair expenses, reduced downtime, and increased building safety. Also, modern non-corrosive reinforcement materials extend the lifespan of infill walls, making them a sustainable and durable solution.

In regions prone to earthquakes, numerous buildings are torn down and reconstructed because of shear cracks in infill walls, even when their structural stability is unaffected. This is mainly due to concerns about safety, as people are hesitant to use visibly damaged structures. Strengthening infill walls with bed joint reinforcement helps limit damage, prevent unnecessary demolitions, and prolong the lifespan of buildings, ultimately enhancing both safety and cost-effectiveness.

Are there any challenges in implementing bed joint reinforcement in existing RC buildings?

The main challenges are:

- Lack of awareness – Many engineers and builders are still unfamiliar with the benefits.

- Integration into existing designs – Retrofitting requires proper planning but is highly effective.

- Material selection – Choosing the right reinforcement type (steel vs. non-metallic) depends on the project needs.

However, with proper training, guidelines, and material selection, these challenges can be easily overcome.

Do you have any real-world examples where bed joint reinforcement has proven effective?

Yes, there are real-world examples of bed joint reinforcement proving effective. In Turkiye, several technical universities have conducted extensive research and testing on this type of reinforcement, leading to its widespread use in both state and private buildings, including hospitals, schools, and government structures.

In earthquake-prone countries, many buildings are demolished and rebuilt due to shear cracks in infill walls, even if their structural integrity remains intact. This happens because people feel unsafe using visibly damaged buildings. By reinforcing infill walls with bed joint reinforcement, we can minimize damage, reduce unnecessary demolitions, and extend the service life of buildings, ultimately improving safety and cost efficiency.

What steps should be taken to promote wider adoption of bed joint reinforcement?

To make this solution standard practice in earthquake-prone areas, we need to:

- Raise awareness – Educate engineers, architects, and construction firms about the benefits.

- Update building codes – Require bed joint reinforcement in seismic design standards.

- Encourage retrofitting – Promote incentives for upgrading existing buildings.

- Focus on non-structural damages – Such as reinforcing infill walls for resilience.

With the right regulations, training, and industry support, bed joint reinforcement can become a great solution for earthquake-resilient buildings.

Conclusion

Bed joint reinforcement is a proven, cost-effective method to improve the seismic performance of infill walls in RC buildings. By enhancing wall strength, reducing damage, and extending service life, it plays a critical role in having more earthquake-resilient buildings.

As awareness grows and more projects adopt this technology, we expect to see a significant shift toward safer, more resilient buildings in seismic zones.

👉 Stay ahead with the latest insights! Subscribe to our newsletter below to receive updates on new blog posts — delivered straight to your inbox.