Briksy

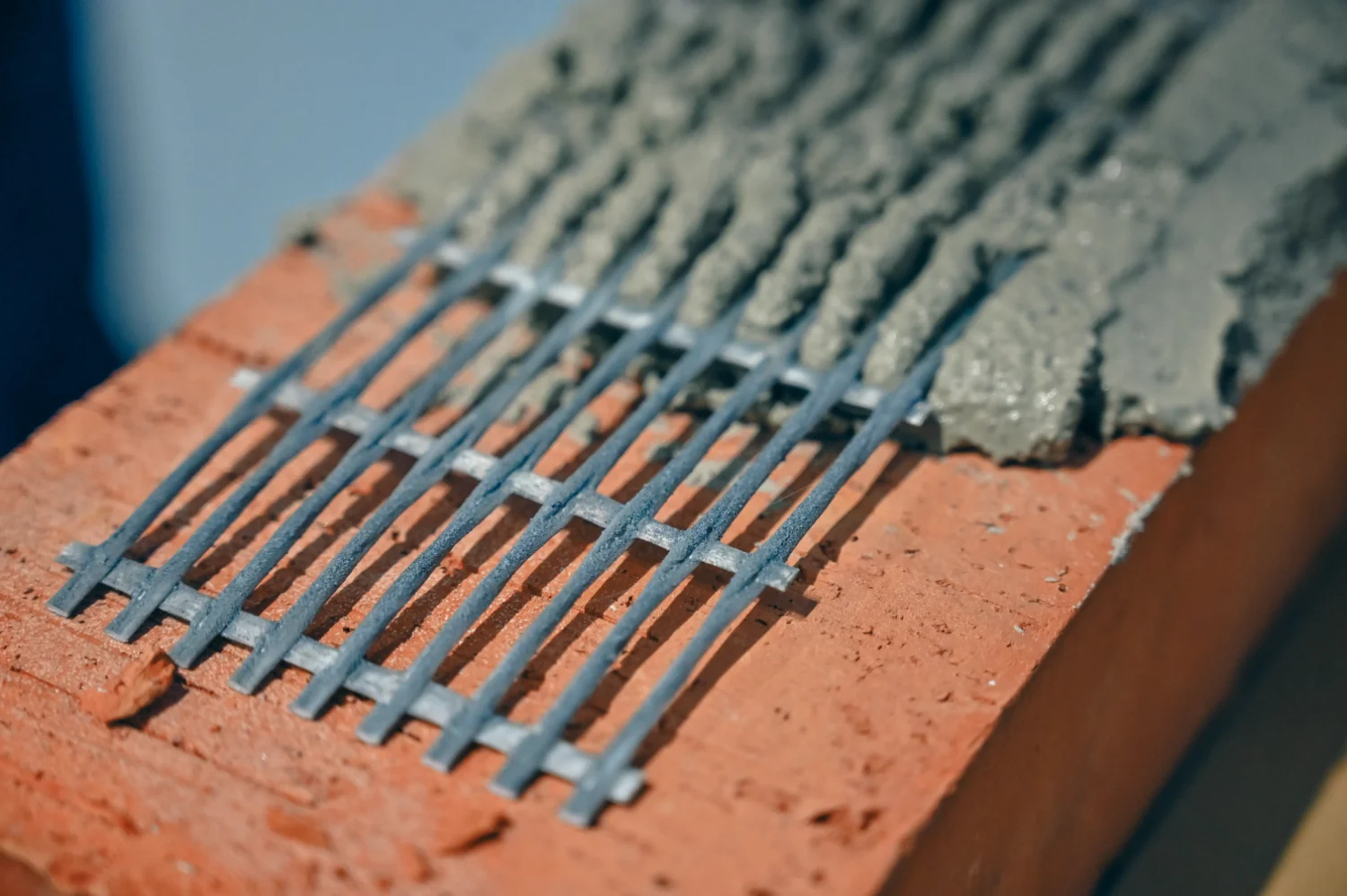

solidian Briksy is a high-tech, non-corrosive glass or carbon fiber mesh used as bed joint reinforcement in masonry. It is placed directly in the mortar between masonry units and helps to reduce the formation and propagation of cracks in walls, especially around window and door openings and in zones of stress concentration.

Thanks to alkali-resistant fibers and special impregnation, Briksy maintains its function even in demanding environmental conditions, without the risk of corrosion associated with traditional steel reinforcement. The thin mesh is fully embedded in the mortar joint and is supplied in long rolls that can be easily cut to length on site – reducing the number of overlaps and speeding up installation.

solidian Briksy is suitable for a wide range of masonry projects – from residential and commercial to industrial buildings. Whether used in new construction or refurbishment, Briksy contributes to long-term durability and more reliable wall behavior over the service life of the structure, with improved crack control and a more even distribution of stresses in the masonry.

The solidian Briksy Carbon variant is tested according to EN 846-2 as bed joint reinforcement in masonry, with verified bond properties between the mesh, the mortar, and the masonry units.

solidian Briksy carries the CE mark based on EAD 260057-00-0303 “Inorganic fibre grid for reinforcement of cement-, anhydrite-, or resin-based screed.”

Learn more about solidian Briksy

Product Features

- High Performance: Reinforces walls effectively, minimizing the risk of cracks due to stress or thermal expansion.

- Easy Installation: A flexible mesh available in roll form (max 30cm width) that’s simple to handle on-site; easily cut to the required length without specialized tools.

- Non-Corrosive: Designed for indoor and outdoor use, providing long-term resistance to corrosion and external elements.

- Enhanced Stability: Primarily strengthens in-plane flexural capacity of walls while also reinforcing against out-of-plane movement, particularly beneficial in vertical seismic loading.

- Lightweight and Compact: Allows for effortless transport and handling, reducing logistical challenges on-site.

- Available in Various Widths: Offers flexibility to meet diverse project specifications.

The complete guide to using solidian Briksy effectively

DOWNLOAD

Our official Briksy Guide provides step-by-step instructions, technical data, and best practices for maximizing performance in masonry applications. From installation to reinforcement strategies—everything you need in one place.

Whether you're working on residential walls or large-scale industrial structures, the Briksy Guide supports you through every stage of the process. Learn how to properly space reinforcement, handle overlaps, adapt to seismic conditions, and manage high-stress zones like wall openings or gables. With detailed illustrations, application tips, and technical specs, this guide ensures your masonry projects are executed with precision, safety, and long-term durability in mind.

reinforcements for the future generations

Product Applications

-

Horizontal Application: Apply solidian Briksy in at least one horizontal mortar layer every 500 mm within masonry walls, following NTC 2018 and Eurocode 8 requirements for areas with moderate to high seismic risk.

-

Wall Positioning: Place solidian Briksy at key points, such as corners and joints, to enhance in-plane flexural strength.

-

Corrosion Resistance: Suitable for both indoor and outdoor use, solidian Briksy is non-corrosive, ensuring long-lasting wall reinforcement

-

Optimal Bonding: Ensure solidian Briksy is fully integrated with the mortar for maximum stability.

- Product Performance & Applications

- Certification & Compliance

- Installation & Handling

- Are your meshes suitable for high-load areas?

- Can your reinforcements be used in chemically aggressive environments like parking garages or industrial floors?

- Why is CE certification important?

- Which products are CE-certified for screed reinforcement?

- Is special equipment needed to install these reinforcements?

- Can your meshes be cut on site?

-

solidian Primafloor 130, 145, 340

-

solidian Primafloor C220 and B215

-

solidian ANTICRACK Q43/Q47/Q85/Q95

-

solidian Briksy Carbon

frequently asked questions

Absolutely. Both structural solutions (e.g. solidian ANTICRACK) and screed meshes (e.g. solidian Primafloor) are tested for mechanical performance and crack control under dynamic and static loads.

Yes. Products like solidian ANTICRACK and REMAT are engineered for high-performance use, including resistance to chemicals, de-icing salts, and water ingress. They are ideal for parking decks, warehouses, and production halls.

CE marking ensures compliance with European safety, health, and environmental protection standards. It also simplifies specification in public or regulated construction projects.

The CE-certified group includes:

This covers most standard applications on the market.