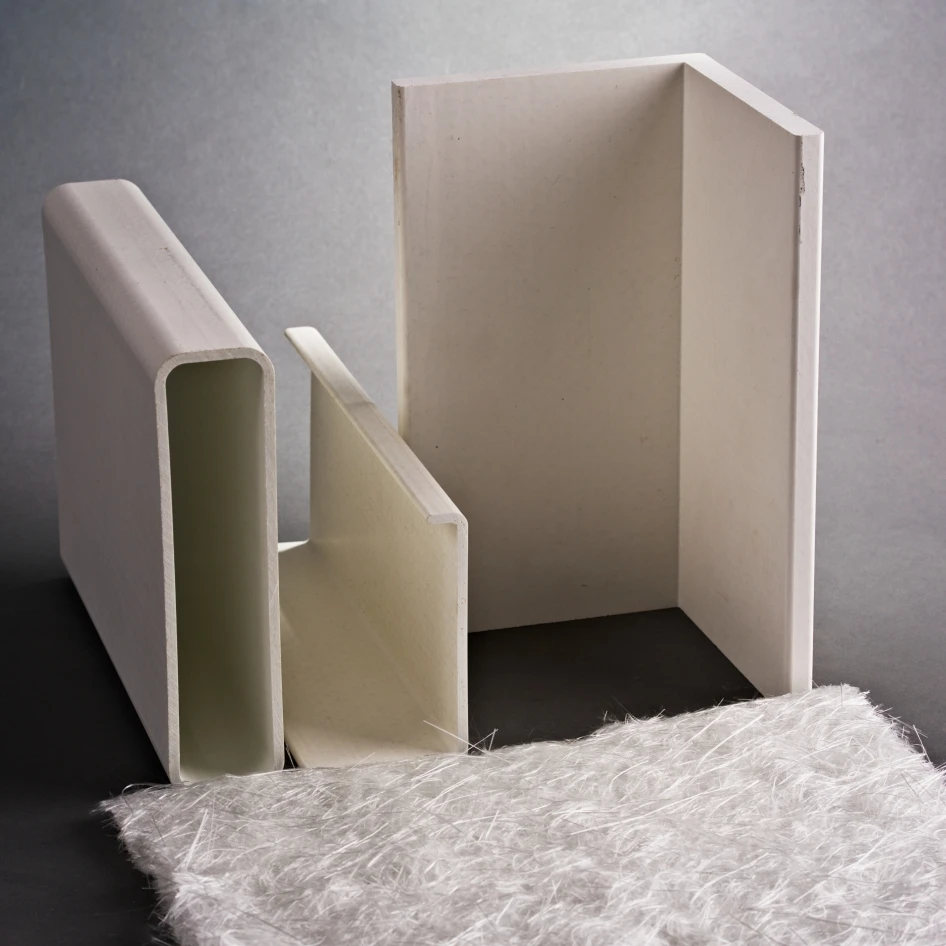

As the composites industry moves toward cleaner, more efficient, and visually refined materials, kelteks FreeMat sets a new standard.

This mechanically bonded, binder-free reinforcement mat is engineered for demanding composite processes — offering both technical reliability and aesthetic performance.

From Pultrusion to Vacuum Infusion, kelteks FreeMat delivers clean processing, strong bonding, and excellent surface results. And in applications where transparency matters, it simply disappears into the resin matrix.

What makes kelteks FreeMat different?

kelteks FreeMat is a high-performance veil designed to improve the manufacturing of composite components across multiple industries.

It is designed to meet diverse performance and needs. Applied within the composite layup, it ensures:

- Uniform resin distribution

- Excellent surface finish

- Stronger bonding

- Reduced process waste

Unlike many traditional mats, kelteks FreeMat contains no chemical binders — resulting in:

- Better compatibility with resins

- Odor-free and emission-free processing

- Improved mechanical properties of the laminate

Why binders are a thing of the past

kelteks FreeMat uses mechanical bonding instead of chemical binders. This technical choice brings several key advantages:

- Perfect resin compatibility – Nothing blocks or slows down resin impregnation

- Cleaner processing – No VOCs, no binders, no unpleasant odors

- Superior laminate quality – Fewer voids, better mechanical consistency

- Improved environmental footprint – No chemical additives = easier recycling, safer for operators

Binder-free = better bonding with resin, environmentally friendly, and easier to process.

An extra advantage: transparency

Thanks to carefully selected raw materials and optimized fiber orientation, kelteks FreeMat becomes virtually invisible when combined with resin.

This makes it ideal for:

- Transparent or semi-transparent applications

- Visually clean composite surfaces

- Decorative laminates with optical clarity

Typical use cases include:

- Water park slides and clear architectural elements

- Aesthetic panels and covers

- Design features where surface uniformity and visual clarity are critical

High performance in advanced composite processes

kelteks FreeMat is compatible with multiple resin processing methods, including:

Pultrusion – High-speed cycles with fewer defects

- Maintains stable fiber orientation

- Provides uniform resin flow

- Reduces voids and improves profile consistency over long lengths

RTM (Resin Transfer Molding) – Clean, fast, and precise

- Conforms perfectly to the mold

- No fiber breakage or displacement

- Shorter cycle times, superior surface finish

Vacuum Infusion – Controlled flow, excellent results

- Enables fast and uniform resin penetration

- Reduces risk of dry spots and scrap

- Supports consistent fiber positioning

Where kelteks FreeMat is used

kelteks FreeMat is already implemented in high-performance applications across industries:

- Construction – Panels, profiles, reinforcements with clean surfaces and high strength

- Automotive & Marine – Lightweight components, structural and interior parts

- Industrial Equipment & Energy – Tanks, covers, housings, corrosion-resistant elements

- Amusement & Sport – Transparent slides, designer elements, canoes, and more

Whether your application is structural or aesthetic — kelteks FreeMat adapts to your process and enhances your product.

Why choose kelteks FreeMat?

kelteks FreeMat combines technical reliability, clean processing, and visual clarity in one material.

It’s designed for engineers and manufacturers who need:

- Efficient production cycles

- Superior surface quality

- Robust mechanical performance

With binder-free construction, multiple format options, and proven performance in real-world projects, kelteks FreeMat gives you the confidence to innovate — without compromising on process stability or product quality.

Explore how kelteks FreeMat can improve your composite manufacturing — from Pultrusion lines to complex RTM projects.

👉 Visit the kelteks FreeMat Product Page

👉 Request a free sample for testing in your production → Let’s find the best solution for your process.