Large-format tiles are redefining modern interior and architectural design, offering seamless aesthetics and a luxurious finish. However, their production comes with significant challenges—ensuring durability, preventing breakage, and maintaining structural integrity throughout manufacturing, transportation, and installation.

As the demand for thinner, larger, and more sophisticated tiles grows, reinforcement solutions have become a key factor in ensuring product quality. kelteks WOVEN ROVING glass is already trusted by leading Italian and Spanish tile manufacturers, helping them produce stronger, more resilient tiles without compromising on design.

To explore how reinforcement technology is shaping the future of the tile industry, we speak with Maja Fuček Doždor, a sales specialist in composites, about the challenges manufacturers face, the advantages of kelteks WOVEN ROVING glass, and what it takes to stay competitive in an evolving market.

Large-format tiles have become extremely popular in modern interior design. What are the main challenges manufacturers face, particularly regarding cracking and durability during production, transportation, and installation?

Large-format tiles offer an elegant and modern look, but their increased size also brings significant structural challenges. The most common issue manufacturers face is brittleness—larger tiles have a higher risk of cracking and breaking during production, handling, and installation.

Another challenge is flexibility—traditional ceramic tiles are rigid, and when subjected to stress, they are prone to failure. This is especially problematic during cutting, transportation, and application on non-perfectly even surfaces. Additionally, as tiles become thinner to reduce weight and improve ease of use, they also become more fragile, making reinforcement essential.

What key factors affect the mechanical strength and longevity of large-format tiles, and why do they require additional reinforcement?

Several factors influence the durability of large-format tiles, but the three most important are:

- Material composition – Without reinforcement, large-format tiles lack sufficient tensile strength and resistance to bending forces.

- Thickness – The trend toward ultra-thin tiles (3-6 mm) makes them more fragile, increasing the need for advanced reinforcement.

- Production and installation stress – Cutting, drilling, and handling large tiles increase mechanical stress, leading to potential microcracks and failures.

To compensate for these risks, reinforcement technologies like kelteks WOVEN ROVING glass significantly enhance flexibility, impact resistance, and overall tile stability.

How does kelteks WOVEN ROVING glass address these challenges, and what makes it superior to other reinforcement methods?

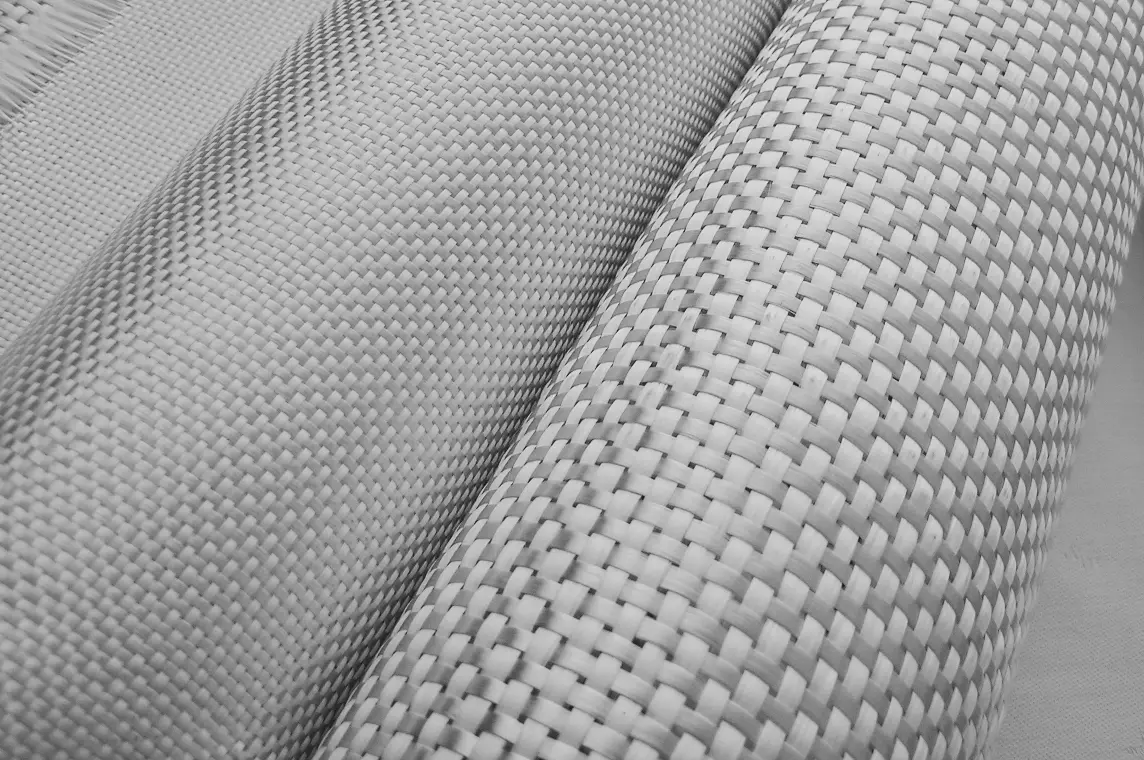

kelteks WOVEN ROVING glass is a woven fabric made from high-quality glass fibers, designed to enhance the strength, flexibility, and durability of ceramic and porcelain tiles.

What sets it apart from other reinforcement methods?

- Higher tensile strength – Provides exceptional mechanical performance while maintaining a low weight.

- Even stress distribution – Unlike standard fiber reinforcements, the woven structure allows for better energy absorption and resistance to cracking.

- Improved flexibility – Allows tiles to withstand stress without breaking, making them more resistant during transport, handling, and installation.

- Lightweight and easy to integrate – Unlike polymer or resin-based reinforcements, kelteks WOVEN ROVING glass does not add significant thickness or weight.

With our in-house development and production, we ensure consistent quality and tailored solutions for each customer’s needs.

Leading Italian and Spanish tile manufacturers already use kelteks WOVEN ROVING glass in their production lines. What convinced them to choose your solution?

The main reason leading tile producers trust kelteks WOVEN ROVING glass is the proven performance and reliability of our reinforcement solutions. These manufacturers needed a lightweight, high-strength material that enhances durability without affecting tile thickness or design.

Additionally, our long-standing expertise in composite reinforcements and ability to customize products to meet individual production requirements made us the preferred partner. We work closely with our customers, offering technical support, testing, and optimization to ensure the best reinforcement solution for their specific tile formats.

How does introducing kelteks WOVEN ROVING glass affect the manufacturing process? Does it require modifications to existing production lines?

One of the biggest advantages of kelteks WOVEN ROVING glass is that it integrates seamlessly into existing production processes. It is applied as a backing layer during tile manufacturing, providing reinforcement without requiring significant modifications to equipment or workflow.

Manufacturers can continue using their current production lines while enhancing the mechanical properties of their tiles with minimal adjustments. Our technical team also supports process optimization, ensuring smooth integration.

Are there long-term cost savings due to reduced breakage rates and improved tile resistance during transport and installation?

Absolutely. By reinforcing large-format tiles with kelteks WOVEN ROVING glass, manufacturers experience:

- Fewer rejected tiles during production, reducing material waste.

- Lower breakage rates during packaging, transport, and handling.

- Stronger and more durable tiles, leading to fewer complaints and claims from customers.

This translates into significant cost savings over time while also improving brand reputation and customer satisfaction.

How can tile manufacturers leverage reinforced tiles as a competitive advantage in the market?

Reinforced tiles offer multiple advantages, which can be strong selling points for manufacturers:

- Stronger and more durable tiles – A key selling feature for customers seeking premium-quality materials.

- Improved workability – Easier cutting, drilling, and installation reduce damage on-site.

- Sustainability benefits – Lighter tiles reduce transportation emissions and overall material waste, aligning with green building trends.

By integrating kelteks WOVEN ROVING glass, manufacturers can differentiate themselves in the market and meet the increasing demand for high-performance, sustainable tiles.

Can materials like kelteks WOVEN ROVING glass become the industry standard for large-format tile reinforcement?

Yes, and we are already seeing a growing adoption of advanced reinforcement materials in the tile industry. As large-format tiles continue to gain popularity, reinforcement will become essential rather than optional.

We believe kelteks WOVEN ROVING glass will play a key role in shaping the future of high-performance ceramic and porcelain tiles, providing a balance between strength, flexibility, and design freedom.

Conclusion

With kelteks WOVEN ROVING glass, manufacturers can produce stronger, lighter, and more durable large-format tiles, reducing waste and improving overall product quality. As demand for high-performance and sustainable construction materials grows, integrating advanced reinforcement solutions is no longer just an advantage—it is a necessity.

Would you like to explore how we can support your production needs?

Contact us today and let’s create the next generation of premium tiles together.

👉 Stay ahead with the latest insights! Subscribe to our newsletter below to receive updates on new blog posts — delivered straight to your inbox.