Skepticism is healthy in construction. New materials must earn trust, and asking tough questions is part of responsible engineering and building practice. At solidian & kelteks, we welcome that. This FAQ addresses the key concerns professionals raise when considering solidian Briksy bed joint reinforcement.

Below are the most relevant questions and transparent, fact-based answers.

1. Does solidian Briksy really help prevent cracks?

Yes.

solidian Briksy strengthens the wall’s in-plane performance, reducing cracks caused by bending, thermal expansion, and shrinkage.

The Guide explains how solidian Briksy forms a continuous tensile network that helps control cracking in long walls, above openings, and in transition zones above the floor plate.

2. Can you guarantee that no cracks will appear?

No manufacturer can guarantee zero cracking, because cracks depend on many factors: design, foundations, masonry quality, execution, loads, and environmental effects.

What solidian Briksy does offer, validated by EN 846-2 testing, is:

- improved tensile capacity

- better stress distribution

- significant reduction of typical masonry cracking

3. How can I be sure solidian Briksy bonds properly with mortar and works as a system?

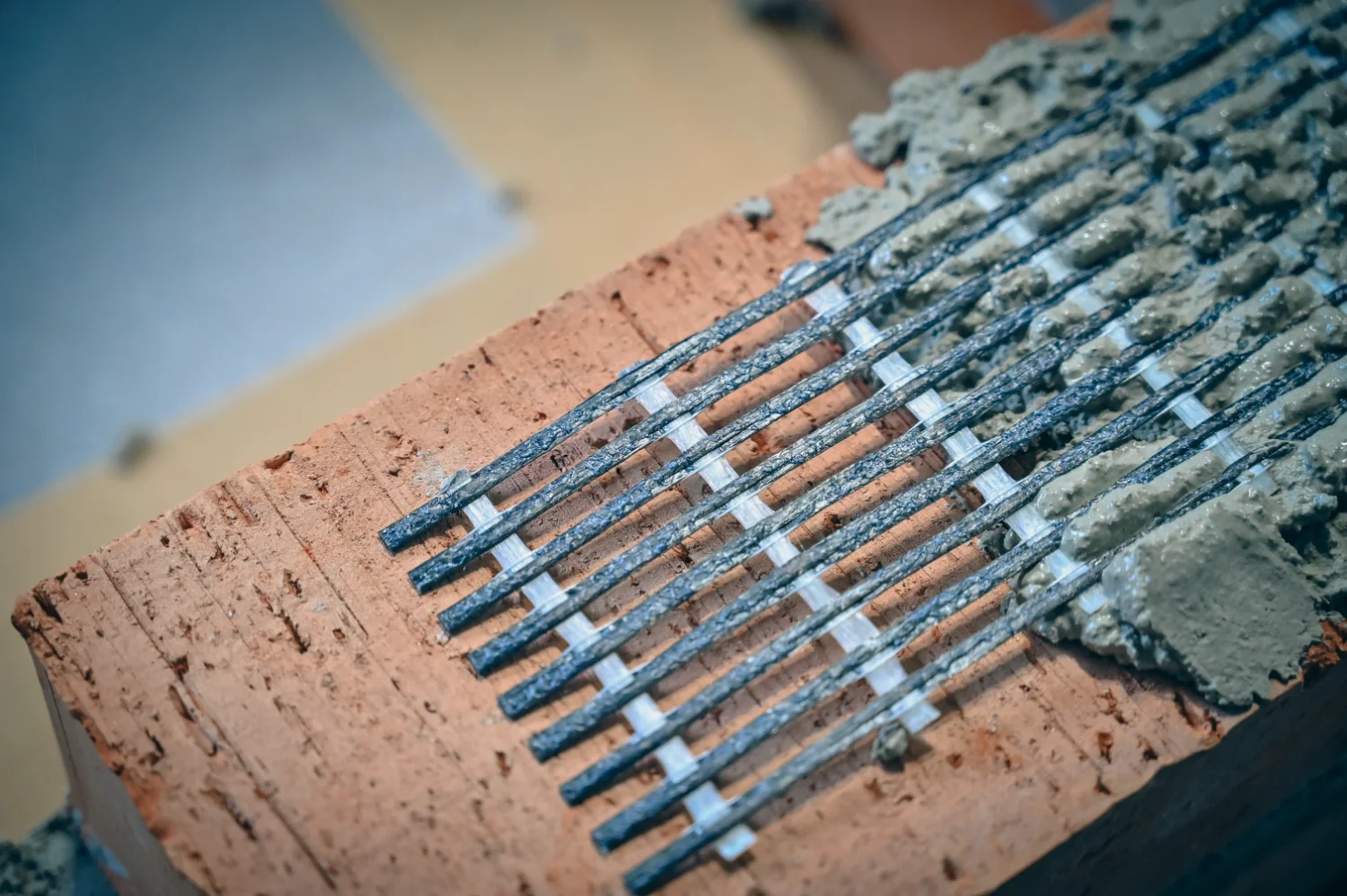

solidian Briksy is engineered to achieve a reliable bond with mortar, ensuring that the reinforcement and masonry act together as a single system.

Its specially designed surface geometry and fibre structure improve mechanical interlock with the mortar, leading to high pull-out resistance and stable long-term performance. In addition, a dedicated filler within the grid further enhances the bond between the fibres and the surrounding mortar matrix, contributing to overall wall integrity.

4. How does solidian Briksy improve out-of-plane behaviour, especially in seismic or wind-loaded walls?

solidian Briksy contributes to both in-plane and out-of-plane wall stability by providing tensile reinforcement close to the zones where stresses are highest.

Because the reinforcement is non-corrosive, solidian Briksy can be placed closer to the wall edge than steel reinforcement, while still maintaining a thin mortar cover (typically around 5 mm) to ensure proper mortar bonding to all fibres. This positioning improves the wall’s response to bending, impact, and seismic actions, where the outer zones of the wall are most critical.

5. Can solidian Briksy be used throughout the full height of the wall?

Yes.

Typical installation spacing is around 500 mm vertically (every 3–4 brick courses). In seismic regions, regulations such as NTC 2018 often require bed joint reinforcement at these intervals over the full wall height.

For taller walls or safer structures exposed to higher loads, solidian Briksy can be installed at smaller vertical spacings (for example 200–300 mm). This should be considered as a recommendation, with final spacing always defined by the project designer based on structural requirements and local regulations.

6. How fast is solidian Briksy to install?

Very fast.

solidian Briksy comes in lightweight rolls, cuts easily, and installs like a regular mortar joint. No special equipment or training is required.

Its ease of handling is highlighted in the Guide.

7. Do I need special tools to cut it?

No.

Standard scissors, mesh cutters, or a utility knife are sufficient.

No grinders, no sparks, no protective coatings required.

8. Will solidian Briksy shift when I place the next brick?

Not when installed correctly.

After solidian Briksy is placed into fresh mortar, the next brick bed stabilizes it.

The installation sequence (mortar – Briksy – mortar – brick) is clearly explained in the Guide and prevents displacement during construction.

9. What is the minimum overlap?

The required overlap is 250 mm, and overlaps should be staggered vertically so they do not align in subsequent courses, ensuring continuous reinforcement.

10. Is solidian Briksy compatible with my mortar system?

Yes.

solidian Briksy is designed to bond with traditional mortar and thin-layer mortar typically used with AAC blocks.

Its engineered surface promotes effective bonding between the reinforcement and the mortar, ensuring reliable load transfer and crack control within the masonry system.

11. What types of bricks and blocks can solidian Briksy be used with?

solidian Briksy is compatible with a wide range of masonry units, including:

- clay solid bricks

- clay perforated bricks

- AAC and solid concrete blocks

This versatility allows the same bed joint reinforcement concept to be used across different masonry systems, simplifying detailing and material selection.

12. How durable is solidian Briksy? What about moisture, frost, salt, or UV?

solidian Briksy is fully corrosion-free and designed for long-term indoor and outdoor use.

The resin matrix protects the fibres from alkaline mortar environments, moisture, temperature changes, and chemicals, as described in the Guide’s durability section.

UV exposure should be avoided only before installation, so storage guidelines recommend keeping the rolls covered.

13. How much installation time can I save?

Based on the product’s lightweight handling and no-tool cutting, crews typically report significant time savings, especially on larger masonry projects.

Exact percentages depend on the site setup and can be quantified upon request.

We are here to support you

If you have additional questions or want to discuss your specific project conditions, our technical and sales teams are here to support you. For direct assistance, please reach out through our contact form. We’ll be glad to help you build solid with confidence.