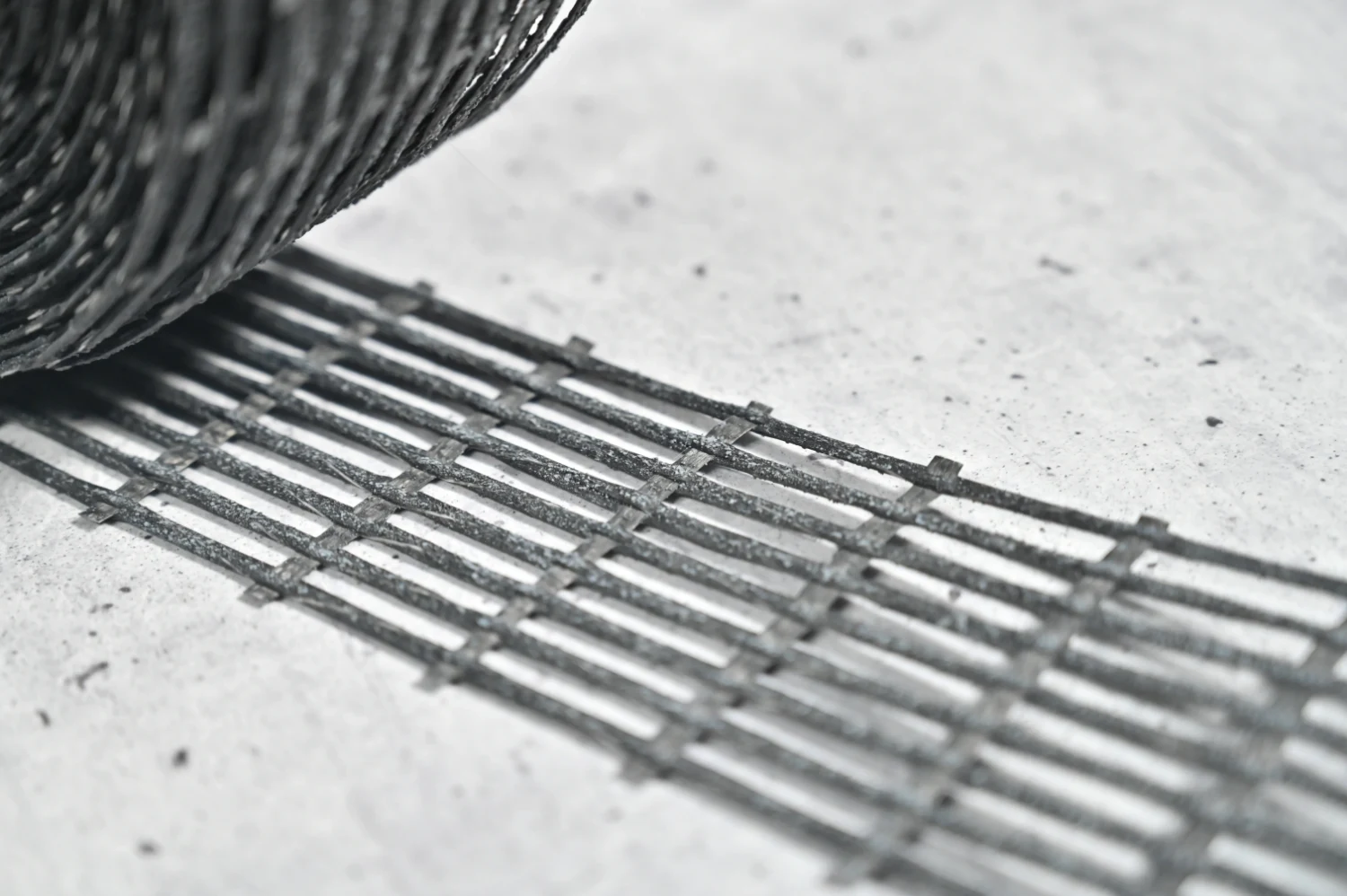

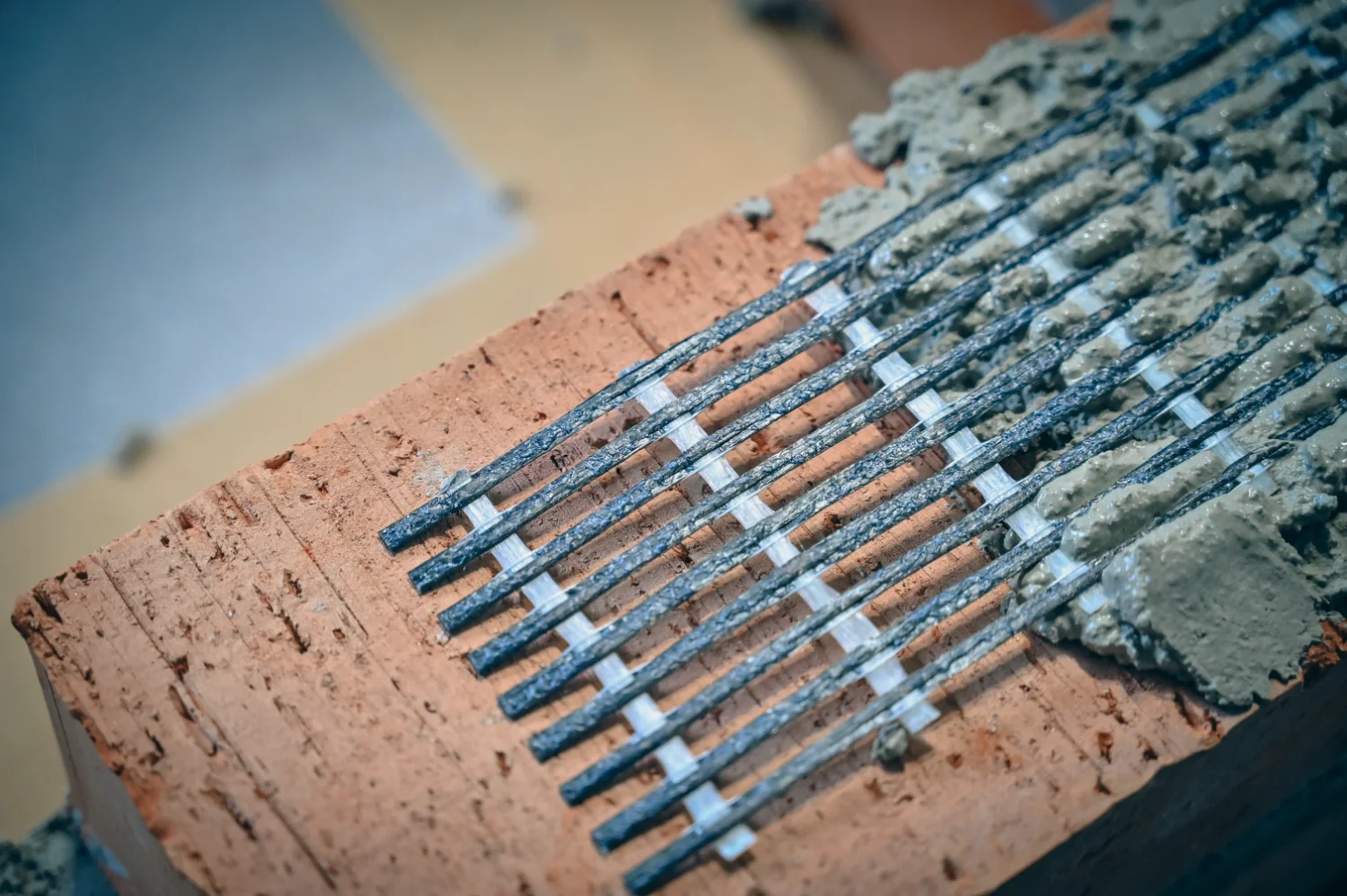

Bed joint reinforcement has become a standard detail in masonry construction - most designers and contractors already specify and install it.

The real question today is no longer “should we use bed joint reinforcement?” but rather:

“What happens to the wall 5, 10 or 20 years from now - and does the choice of material change that outcome?”

This is where the difference between steel and non-corrosive alternatives becomes more than a preference.

It becomes a long-term performance issue.

In this article, we focus on the specific, real-world reasons why engineers, contractors and system providers are moving from steel bed joint reinforcement to solidian Briksy, and what that change actually delivers in practice.

1. Steel Works on Day One - the Problems Start After

Steel bed joint reinforcement is familiar, widely used and easy to specify. However, masonry walls are not judged on the first day of installation.

They are judged on:

- year 5 (first winter cycles)

- year 10 (moisture accumulation)

- year 20 (material degradation)

And inside the mortar joint -the place you cannot inspect - steel corrodes.

Corrosion doesn’t start on the surface - it starts inside the wall

Mortar gradually loses its initial high alkalinity. Moisture migrates through joints. Salts accumulate in exposed zones.

Result:

- steel begins to rust

- rust expands in volume

- the mortar joint is put under internal pressure

- micro-cracks form

- visible cracks and stains appear later

This is often the root cause of:

- hairline cracks above openings

- staining on façades

- diagonal cracks in long walls

- unexplained cracking in parapets and gables

Steel may be standard — but it is not stable.

2. Non-Corrosive Materials Keep Their Properties for the Entire Service Life

solidian Briksy is made from glass or carbon fibres, both fully resistant to corrosion inside the mortar.

This means:

- no loss of cross-section

- no expansion stresses

- no rust-related cracking

- no staining

- no hidden degradation

The reinforcement performs the same on year 20 as on day one.

In exposed areas such as:

- parapets

- balcony walls

- roof edges

- gables

- freestanding walls

…the difference between steel and non-corrosive reinforcement becomes dramatic.

3. Steel’s Thermal Expansion Can Work Against the Wall

Steel expands and contracts with temperature changes more than masonry units. This mismatch creates:

- micro-movements inside the mortar bed

- internal stress accumulation

- potential crack initiation points

With non-corrosive reinforcement (glass or carbon fibres):

- the thermal movement is significantly lower

- the material is more compatible with masonry

- stress transfer is smoother

- crack risk is greatly reduced

This compatibility is one of the main engineering reasons behind the move to Briksy in modern systems.

4. Non-Corrosive Reinforcement Offers Superior Behaviour Around Openings

Openings are the weak points of every wall. This is where:

- tensile stresses peak

- cracks naturally form

- steel corrosion often initiates (due to weak points in construction detailing)

solidian Briksy offers:

- high tensile strength

- no corrosion inside vulnerable zones

- stable performance after freeze–thaw cycles

- better anchoring in the mortar (thanks to slim, consistent fibre grids)

For designers and contractors, this means:

- stronger lintel behaviour

- better crack distribution

- fewer callbacks for cosmetic repairs

5. A note on Out-of-Plane Behaviour (Eurocode Protective Cover)

Steel bed joint reinforcement requires a minimum mortar cover of around 15 mm on each side, as specified in Eurocode guidance, primarily for durability and fire resistance. This means that the steel is positioned deeper within the cross-section, and the outermost zone of the wall is unreinforced.

Non-metallic fibre reinforcement such as solidian Briksy is not governed by steel corrosion in the same way. In principle, fibres can be effective closer to the surface, and distributed fibres can start contributing to tensile load transfer as soon as microcracks form. From a mechanical perspective, this suggests a potential for earlier engagement of the reinforcement under out-of-plane bending and improved crack control in the outer layers of the wall.

While dedicated design provisions for fibre-reinforced masonry are still being developed in European practice, the mechanical behaviour outlined above is in line with current research and applications of non-metallic reinforcement in mortars and concretes. In practice, specific requirements for cover, embedment depth and fire resistance of Briksy reinforcement are defined by the applicable standards, approvals and test results for each project, rather than by this explanatory note.

To conclude: The Material Matters More Than Ever

Bed joint reinforcement is not new. But the way we build today - and the performance we expect from masonry - has changed.

Steel was a solution for another era. Moisture-rich, exposed, fast-paced modern construction demands a reinforcement material that will not deteriorate.

That is what solidian Briksy delivers.

A bed joint reinforcement that:

- does not corrode

- stabilizes the wall

- controls cracks

- protects exposed zones

- keeps façades clean

- and retains performance for decades

All while fitting into the same detailing approach designers and contractors already use.

Explore the Details

For installation guidelines, detailing examples and recommended spacing, see:

→ solidian Briksy - User Guide (PDF)

→ solidian Briksy - Product Page

build solid.