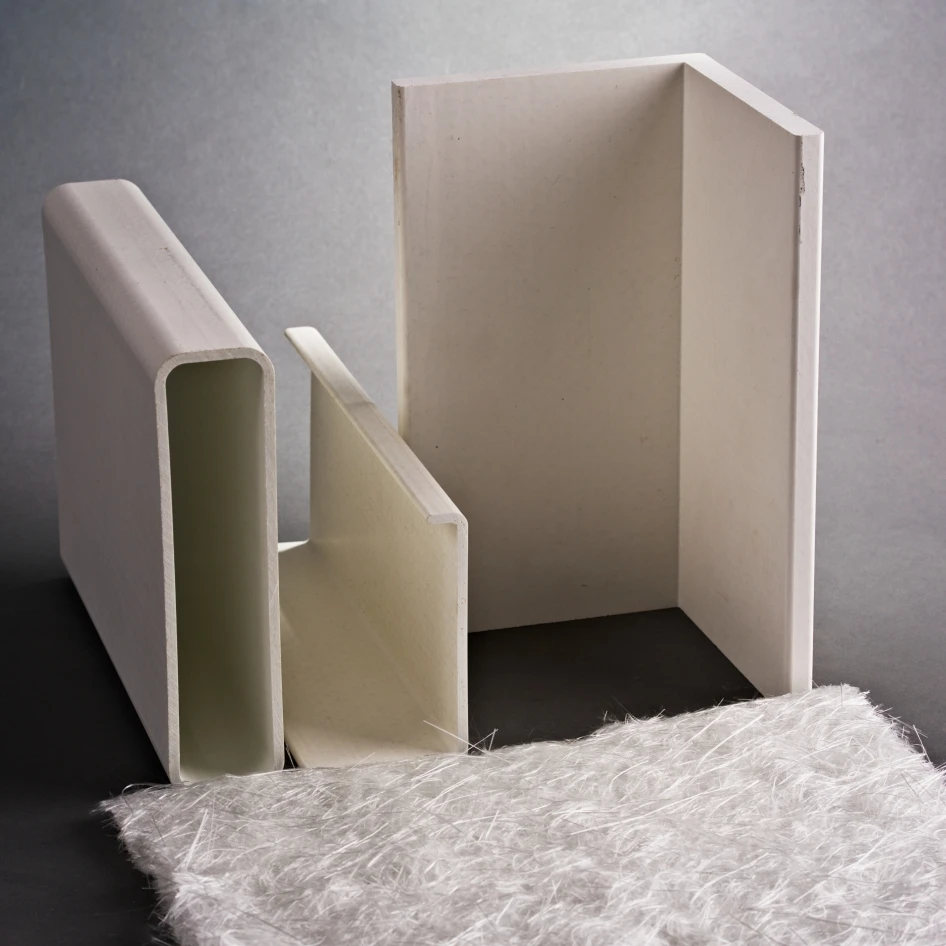

FreeMat

Delivering performance characteristics comparable to continuous filament mats, kelteks FreeMat combines high fiber integrity with tailored processability for demanding composite environments.

Its balanced combination of flexibility and structural integrity makes it ideal for Pultrusion, RTM, Vacuum Infusion and other closed molding processes, ensuring high productivity and quality in advanced composite applications.

Experience the future of composite reinforcement – request your kelteks FreeMat sample today. Our technical team is available to discuss how kelteks FreeMat can transform your composite manufacturing process.

Product Features

- Enhanced mechanical strength from 100% glass fiber structure

- Better bonding & reduced print-through – Enhances adhesion & surface quality

- Truly eco-friendly with zero binders and no harmful processing emissions

- Superior resin penetration reducing material usage and processing time

- Perfect conformability to complex shapes without fiber breakage

- Exceptional durability in aggressive chemical environments

- Universal compatibility with polyester, vinyl ester, and epoxy resins

- Excellent transparency and low fiber visibility

Tailored Performance

Sustainable Manufacturing Options

Binder-free technology eliminates chemical adhesives entirely, creating a cleaner workplace and manufacturing process. The pure glass composition maximizes adhesion and compatibility with all standard resin systems.

Optimize Resin Performance

The open structure of randomly oriented fibers ensures excellent resin penetration and uniform wet-out.

Structural Superiority

With 100% glass fiber construction, both FreeMat variants deliver outstanding tensile and flexural strength. Randomly oriented fibers enhance stiffness and impact resistance, extending composite structure lifespan.

Form Stability & Adaptability

kelteks FreeMat conforms to complex geometries without wrinkling or fiber breakage. The mat structure maintains integrity during resin infusion and pultrusion, ensuring defect-free final components.

Environmental Resilience

Composites reinforced with kelteks FreeMat demonstrate excellent long-term performance in demanding environments, offering resistance to moisture, chemicals, and corrosion that outperforms conventional reinforcements.

reinforcements for the future generations

Product Applications

- Construction & Infrastructure

- Automotive & Transportation

- Energy & Utilities

- Chemical Processing

- Oil and Gas

- Sport & Leisure

Versatile Solutions for Diverse Applications

kelteks FreeMat offers tailored reinforcement solutions, ensuring optimal performance across multiple composite manufacturing processes:

- High-Strength Performance for Pultrusion: Engineered for continuous pultrusion line of high-performance composite profiles which provides exceptional mechanical strength, making it the ideal choice for pultrusion applications where durability and structural integrity are critical.

- Flexibility for Complex in Closed Molds: Provides outstanding flexibility, ensuring seamless formability in Vacuum Infusion, Resin Transfer Molding (RTM), Compression Molding. Its adaptability allows for easy shaping around intricate molds without fiber breakage.

- *Transparency for Specialized Applications (Best suited products: Kelteks FreeMat 900 g/m2): Designed for industries requiring high transparency, such as water park slides and other clear composite panels. Its refined structure ensures clarity and aesthetic appeal while maintaining strength and durability.