ANTICRACK

Smallest crack widths.

Liquid-tight.

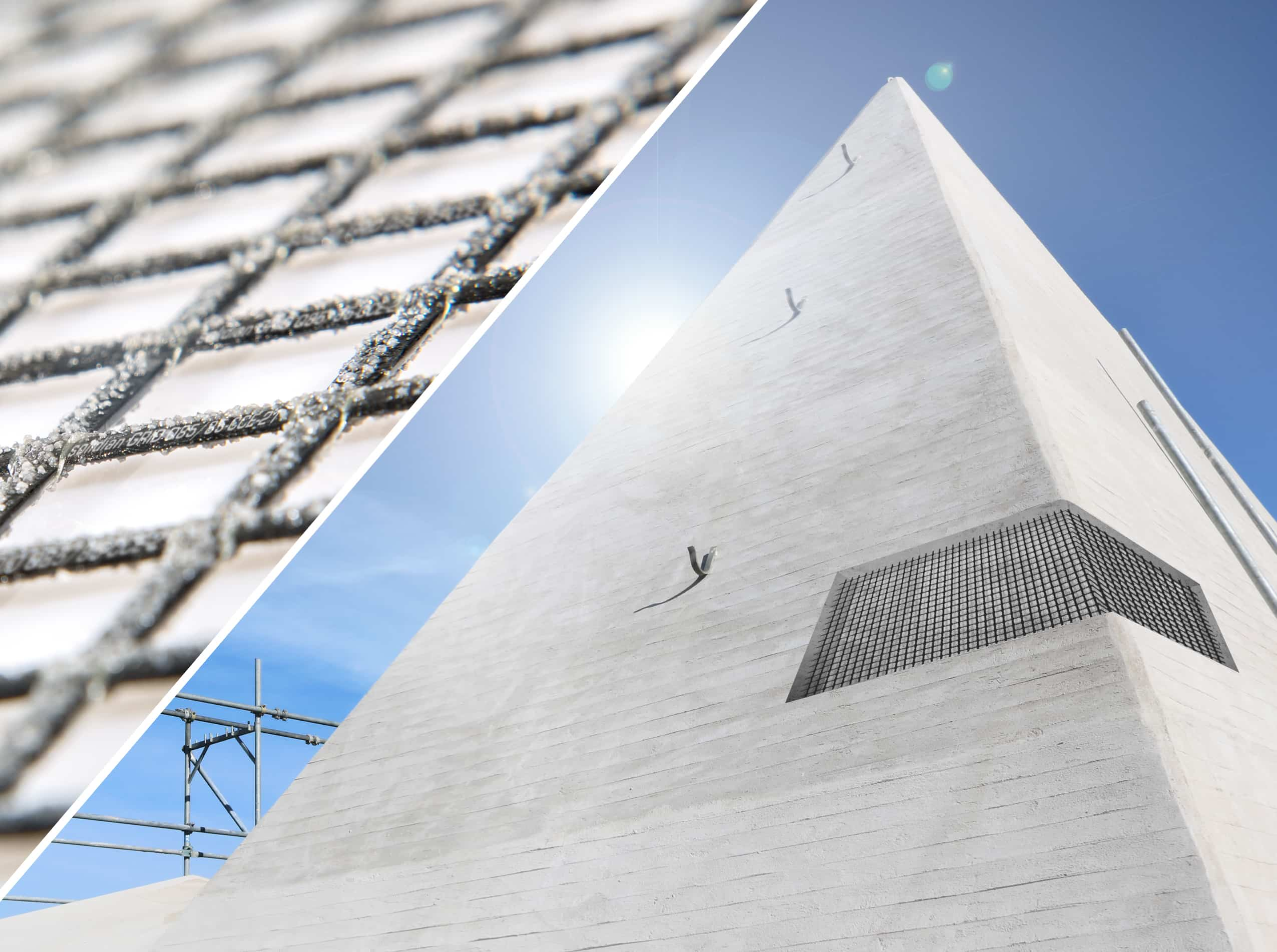

solidian ANTICRACK combines many advantages compared to conventional construction with reinforced concrete. The biggest advantage of our crack limiting reinforcement for concrete is the non-corrosive material with superior bonding behavior – this results in many advantages for the future of building with concrete.

CE-certified per EAD 260057-00-0303 Inorganic fibre grids for reinforcement of cement-, anhydrite- or resin-based screeds. For product performance in this application, please check the Declaration of Performance (DoP) available on Downloads page, under certificates section.

Product Features

- Sanded surface for superior bonding behavior

- Higher tensile strength compared to structural steel

- Much lighter and thinner than steel

- Sustainable material as consumption of water, sand, and cement are significantly lower

- Thinner and safer components and thus less raw material usage and economical transport

- No corrosion

- Less crack widths and therefore much lower repair costs

reinforcements for the future generations

Reference project

Product Applications

Flat and light reinforcement like the solidian ANTICRACK can be used wherever there are requirements for a non-corrosive environment, especially with requirements to limitation of crack widths, optimal distribution of cracks, and short anchorage lengths e.g.

- Restoration, parking decks, industrial floors

- Hydraulic structures

- Tiling and waterproofing: pools, basements

- Protection layers, where concrete layers are applied on a steel-reinforced concrete underground to protect the underground

- Strengthening measures for restoration (e.g. failure of the bottom plate due to excessive load)

- Marine construction, earthquake, bridge constructions, structures that need small crack widths

- Product & Technical Compatibility

- Process Efficiency & Performance

- Use Cases & Application Support

- Which composite manufacturing processes are your reinforcements compatible with?

- Are they compatible with automated production environments?

- How do your reinforcements help improve production efficiency?

- Can your reinforcements be adapted to our production setup?

- Can you help us choose the right reinforcement for our project?

- Are your products suitable for visually demanding applications?

- In which industries are your glass fiber reinforcements commonly used?

frequently asked questions

Our products are suitable for pultrusion, RTM, vacuum infusion, filament winding, and other continuous or closed-mold processes.

Yes. kelteks FreeMat and other glass reinforcements are optimized for high-speed production, offering clean handling and consistent quality across long production runs.

Our products ensure fast resin flow, excellent fiber wetting, and consistent fiber placement, leading to shorter cycle times and reduced scrap rates.

Yes. We can customize roll widths, formats, surface weights, and roll lengths to meet the specific needs of your process or equipment.

Our team provides technical guidance and product samples to help you test and select the best solution for your application.

Yes. Thin reinforcement layers like kelteks FreeMat become nearly invisible after resin infusion, making them ideal for transparent or aesthetic surfaces such as toboggans, water slides, and decorative panels. Check the product gallery here.

Our reinforcements are used in industrial equipment, construction components, transportation, electrical infrastructure, and marine applications. A key segment is the recreational industry, especially waterparks, where materials must be durable, non-corrosive, and visually appealing.